So, for quite a while now I’ve had the need for a CNC controlled plasma cutter. I’ve got a manual one but I’m just not enough of an artist to make good, clean and precise cuts with it.. at least not in sheet metal thicker than a millimeter or two.. So, now that I needed some semi-precise-cut steel sheet for the battery boxes on the E-vant I decided to build the plasma I’ve never got around to building.

But..

I really don’t have the time to fiddle with a DIY build at the moment with the kitchen arriving this week and a surgery for a cyst in my jaw coming up next week so – this’ll be a rush build. I challenged myself to build the entire mechanics for the plasma in one week – this week.. so here goes. I’ll try to update the blog every night..

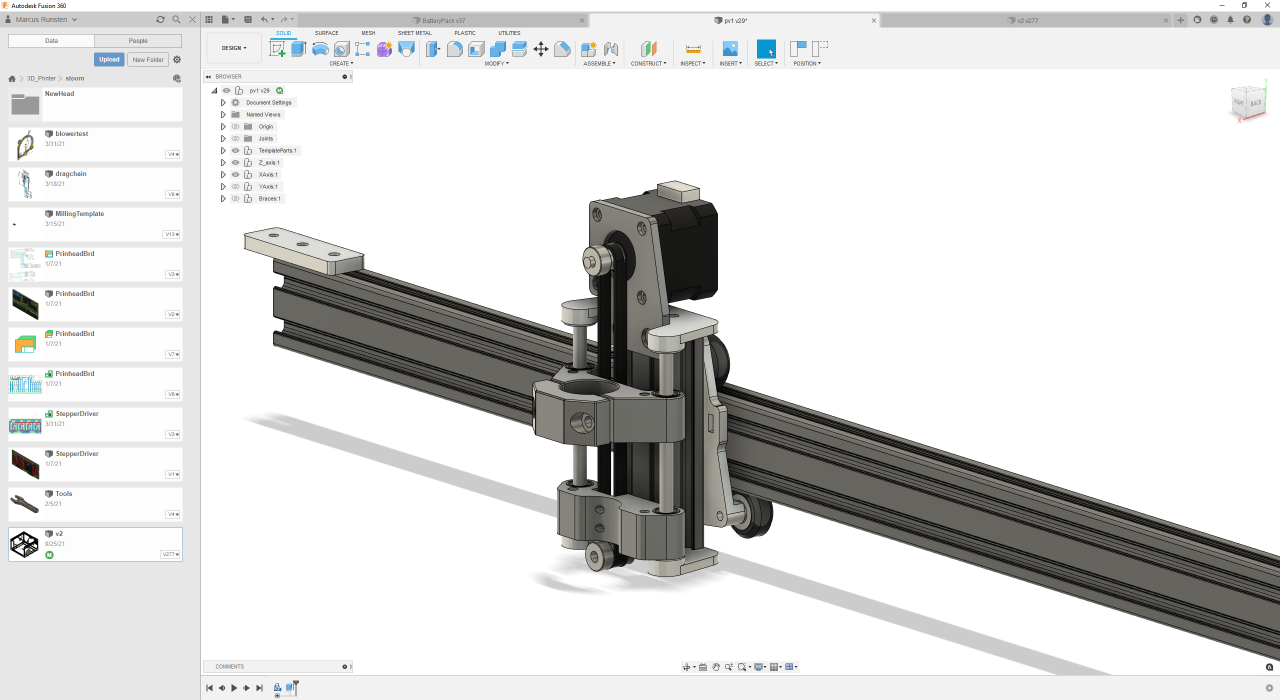

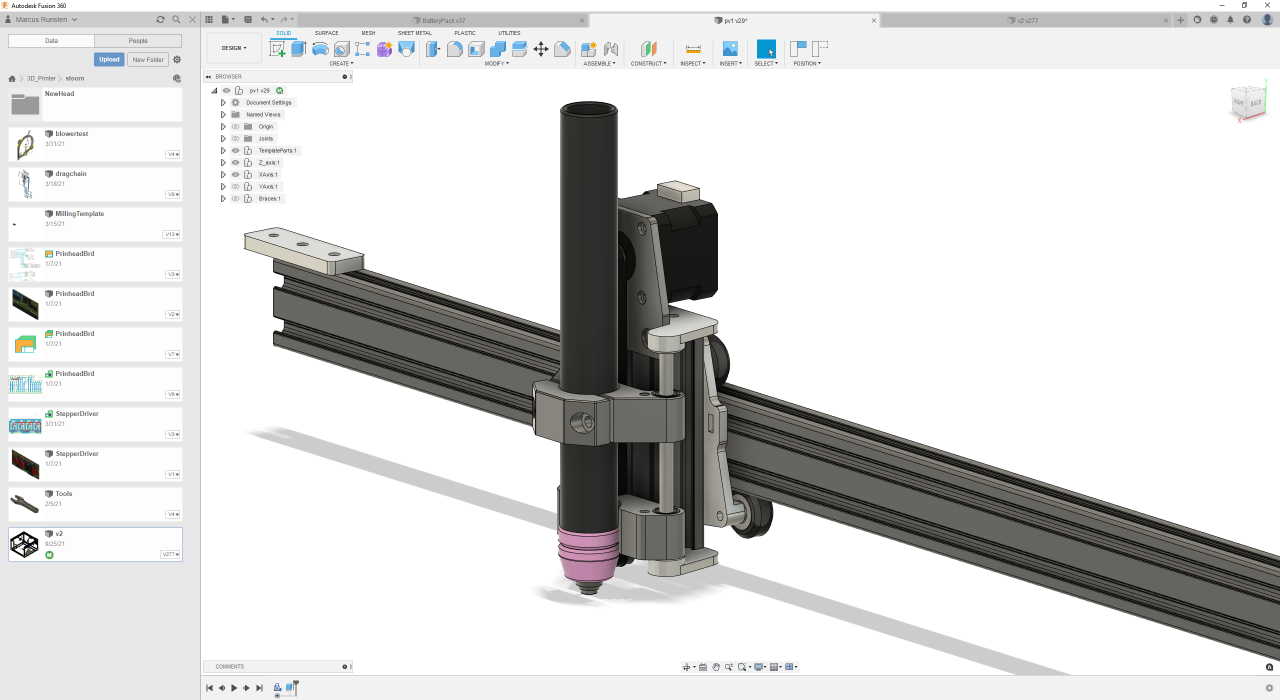

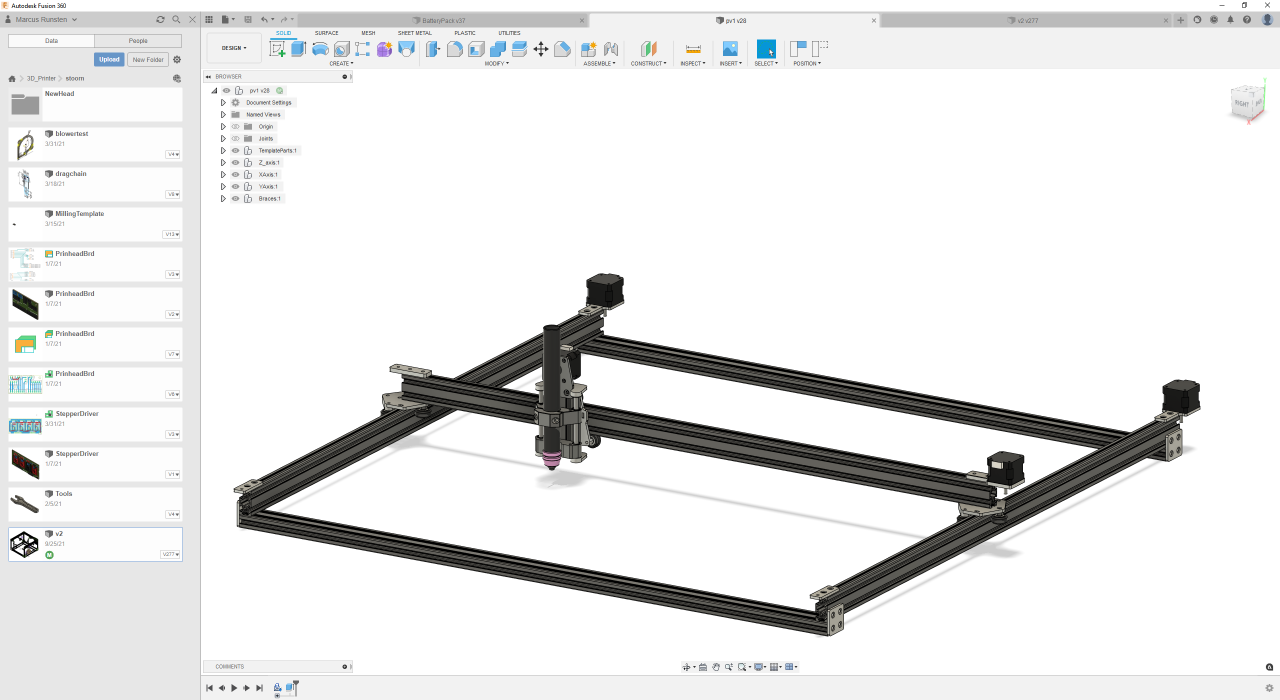

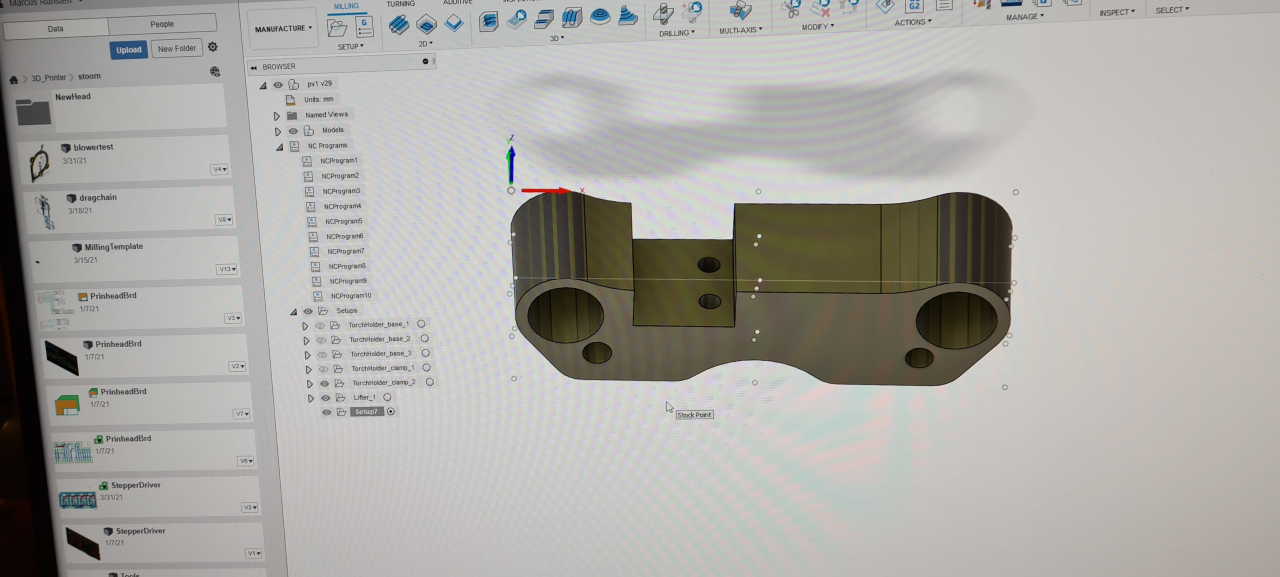

So, today – monday – being the first day of the project I started off doing some CAD. First of all the plasma head holder with the Z axis. This’ll have one cradle holding the torch and another cradle underneath connected to the Z stepper motor. This way I can make the cutter sense the height of the metal sheet and do the scrape ignition of the plasma.. Yeah, I didn’t get the HF-start on the plasma cutter so.. this’ll have to do.

I did however, long ago, get one of those tube-shaped plasma torches so that’s what we’ll use for the CNC..

Making the X and Y gantry and the support frame was a pretty quick job and then.. CAM.

To get the CNC mill to spit out the parts from the raw aluminium blocks you have to prepare the gcode files using a CAM processor. This is where you set up each and every operation the mill has to perform in order to cut the right part the right way. It’s a bit finnicky but after having done this for some time you learn.. I’ve broken many cutters in the process but today I didn’t break a single one.

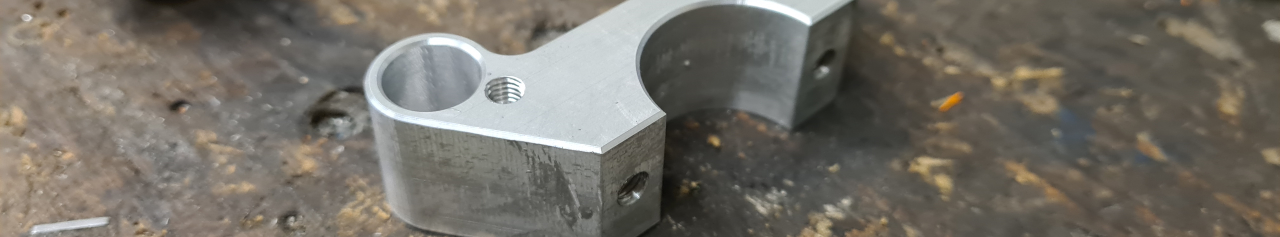

I started off making the most complicated parts. This part, the torch holder, needs to be processed from three different angles. Since I only have a 3 axis CNC-mill I have to mill the first side, then remove the part from the mill, re-fasten it in the next orientation, do all the work from that angle and then do the repositioning all over again. For each time the part is loosened I have to re-zero the X-, Y-, and Z-axis.. which takes some time.. but.. well..

When the mill is done with the first orientation and after a quick chamfer of the part, this is what it looks like..

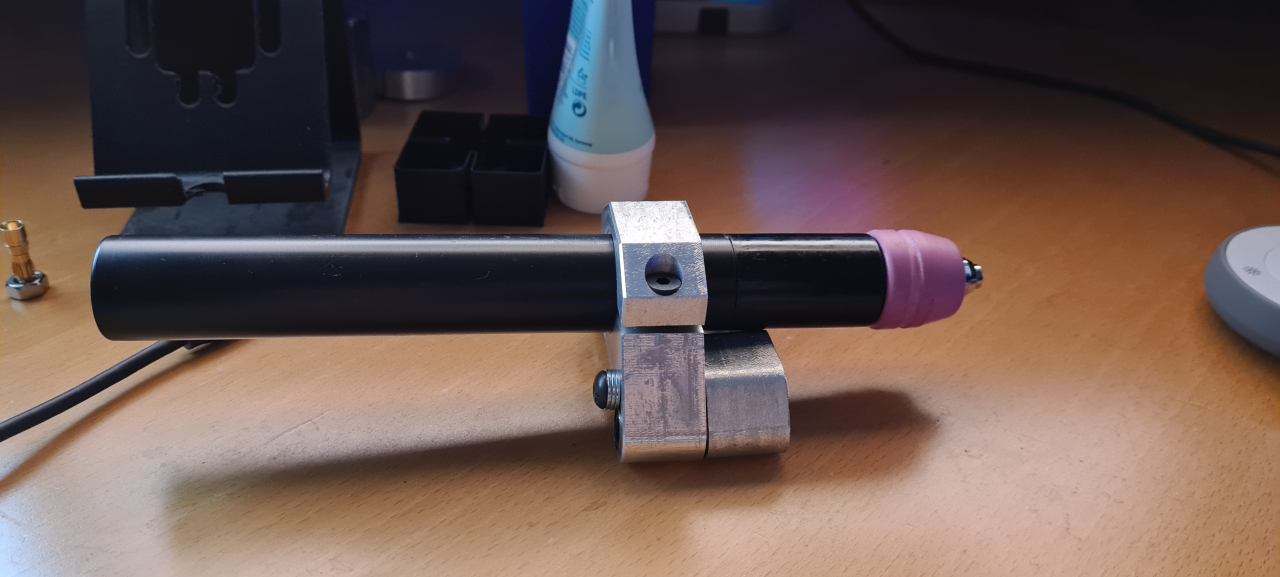

.. and this is the same part after doing all the operations and cleaning it up a little.

I did manage to pick up a 3mm steel sheet during lunch break and this is what the CNC plasma is going to cut the first parts from.. if it ever works.

After making the clamp this is what the torch holder looks like. Fits perfectly!

So, these three parts are what I managed to produce today. They are however the most complicated parts to manufacture by far and the only parts needing operations on more than one side, so the rest of the parts are going to take much less time to manufacture.. So, I’m pretty happy with what I managed to do today..

Stay tuned for the update tomorrow where the Z axis will hopefully be completed and the manufacturing of the X gantry at least started..