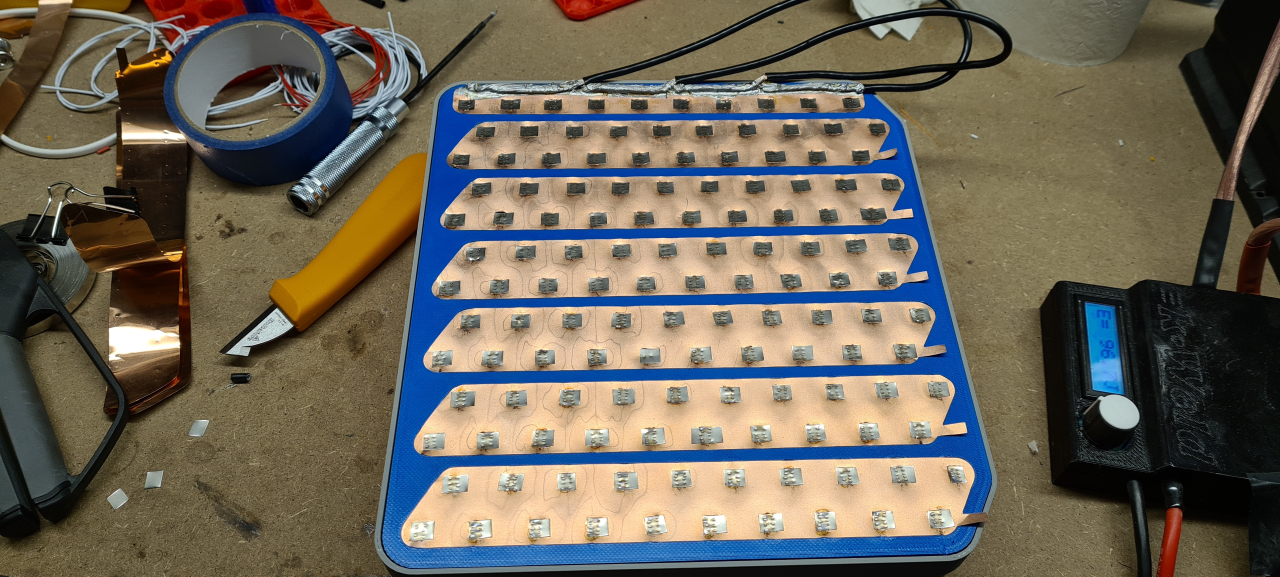

When all the copper plates were welded to the cells and all the BMS wires were added..

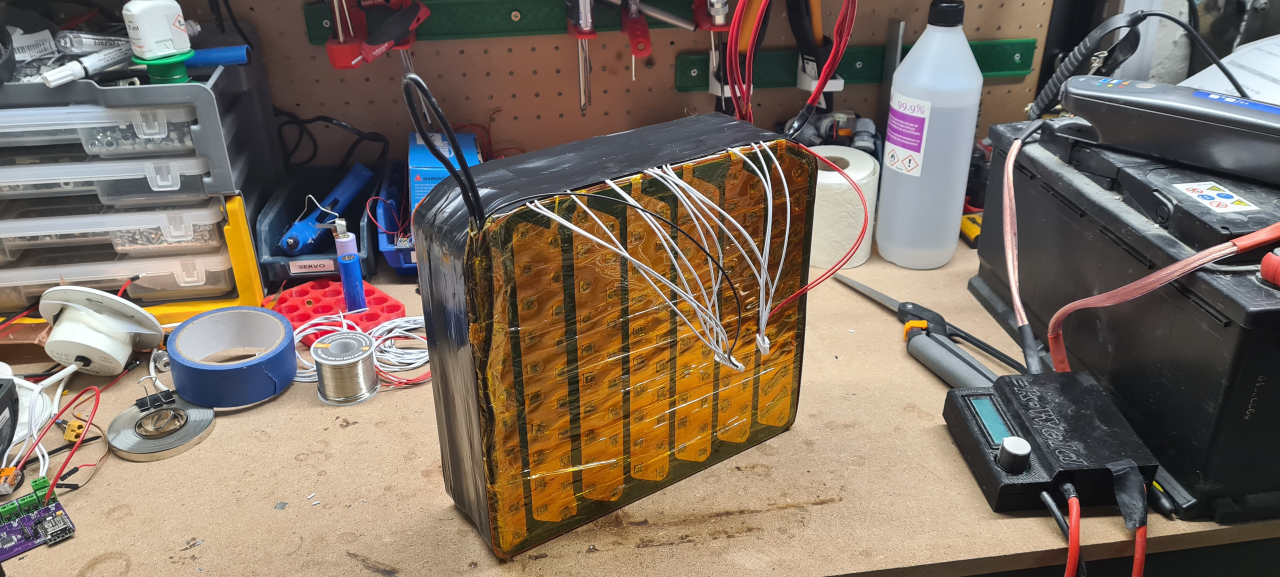

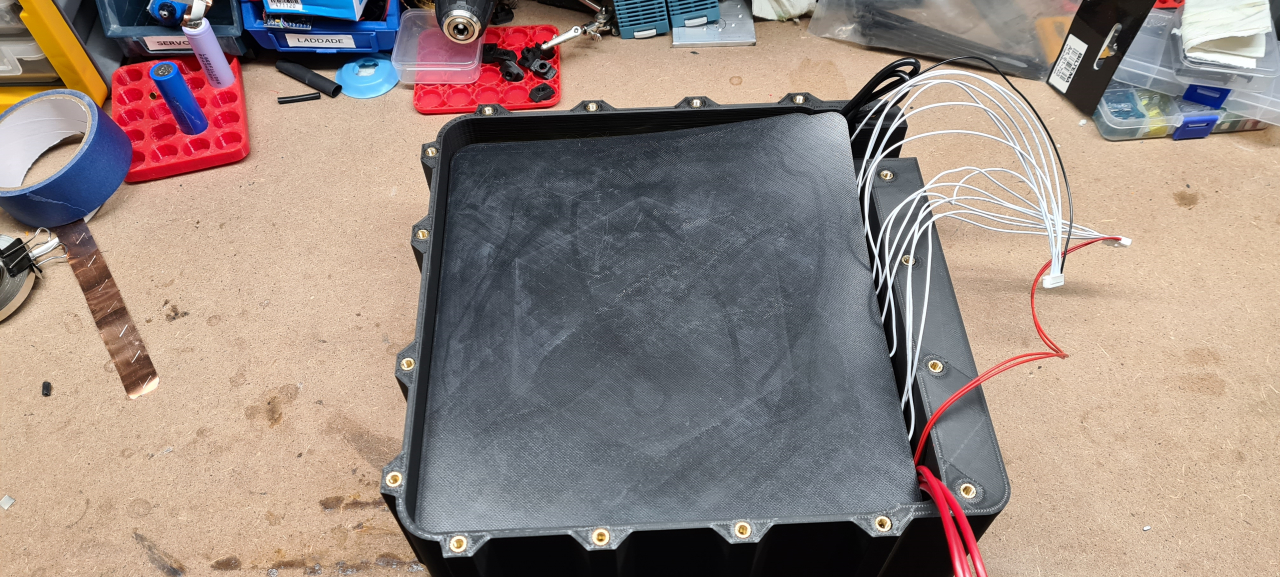

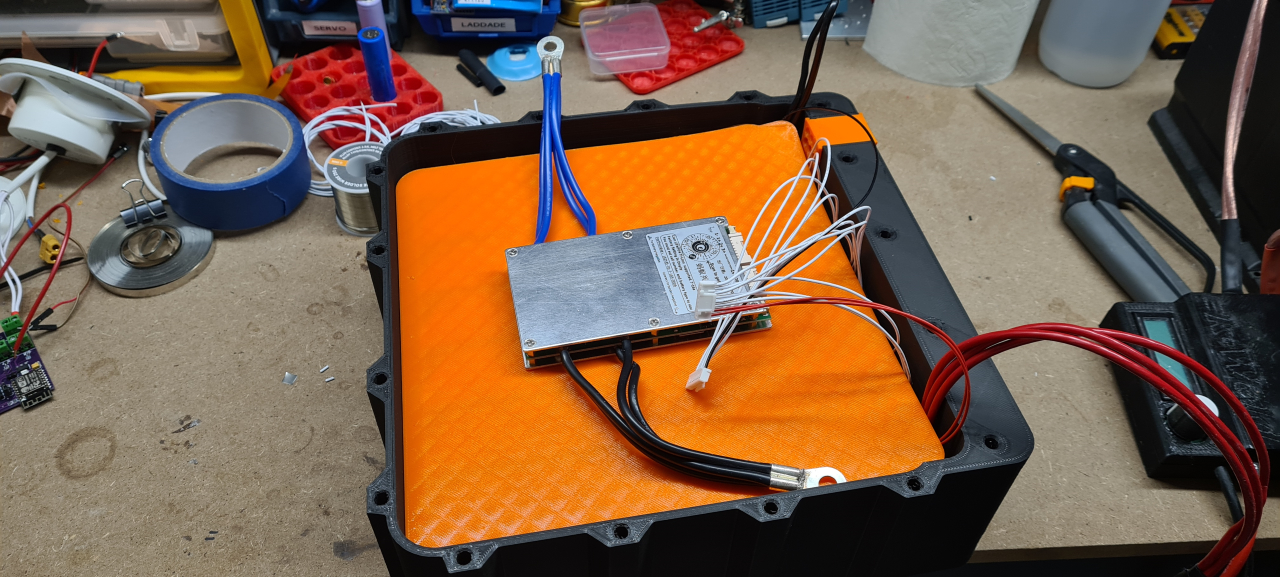

.. it was time to finish the battery build. I printed the box and the TPU divider and put the cell pack in it’s place.

I’ve bought a couple of ANT 300A BMSes to protect the packs and they come with screw terminals mounted.. so I pressed the same type of terminal on the negative leads of the pack..

After that it was just a matter of adding the BMS.

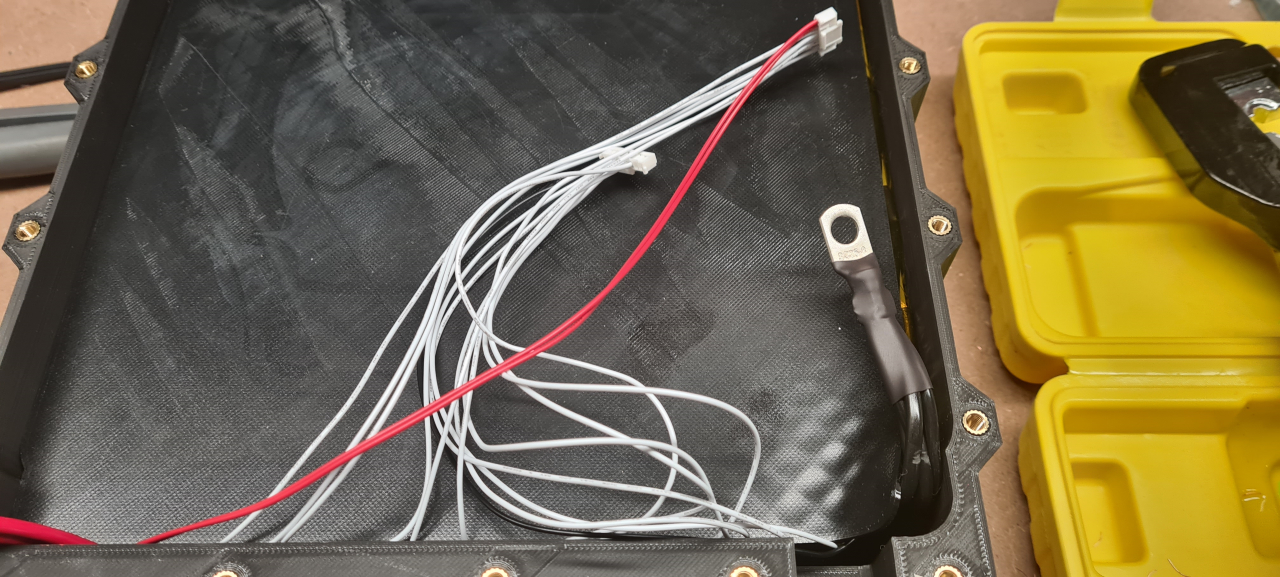

.. connecting all the wires ..

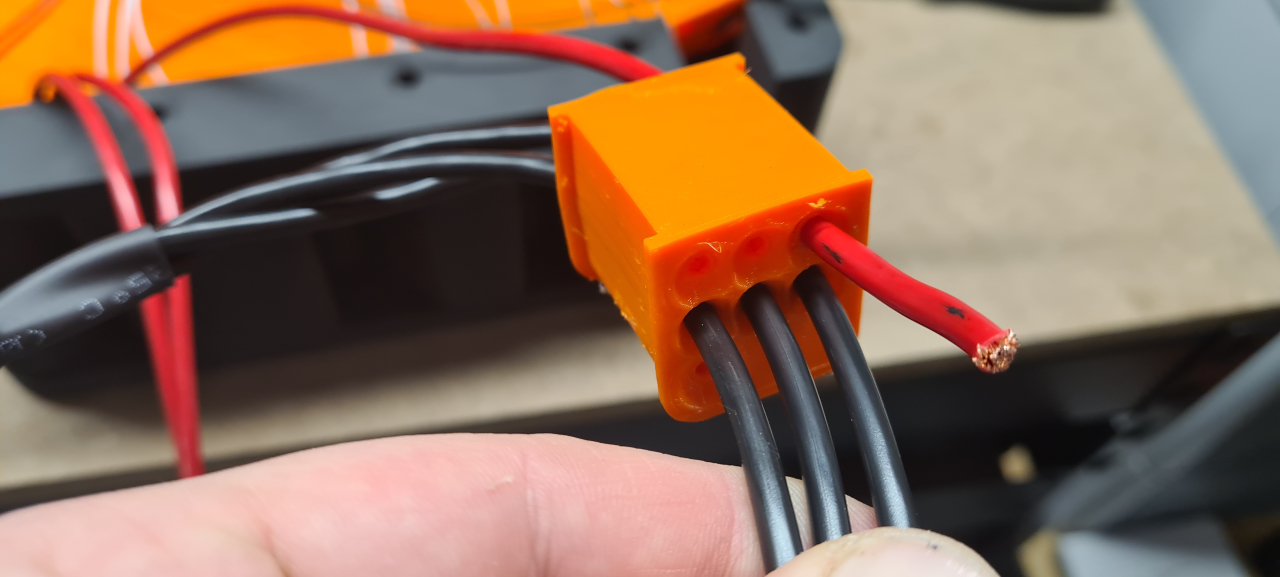

.. and pushing the positive and negative power feeds through the TPU grommet..

To finish the packs I soldered EC5 connectors to the power leads and printed a ”connector” to house the 3 connectors to make it easier to connect the battery pack to the Evant and impossible to connect the wrong leads shorting a battery pack out..

So.. now I’ve got one complete battery pack of 26s10p which gives me a 96V pattery with 30A capacity yielding a whopping 2,9kWh. This is what I’m going to use for testing. I’ve got enough cells to make one more complete setup so that I can charge one pack while using the other. Hopefully I’ll be able to run the machine for at least half an hour on each pack.. Doing the math :

Avant original motor power: 10kW

Estimated mean power output: 33%

Estimated mean power output: 3.3kW

That should give me almost 55 minutes of run time on my pack, but to have some margin let’s say 45 minutes. Charging the pack at 30A (1C) would take more or less an hour to charge the pack fully, so it might be possible to get back to back running.. otherwise I can build one more pack to have two packs charging while I’m running the third. That should give me continous driving with pretty good margins but it’d cost me approx $700 to build.. We’ll see how it works, only testing will tell..

TBC