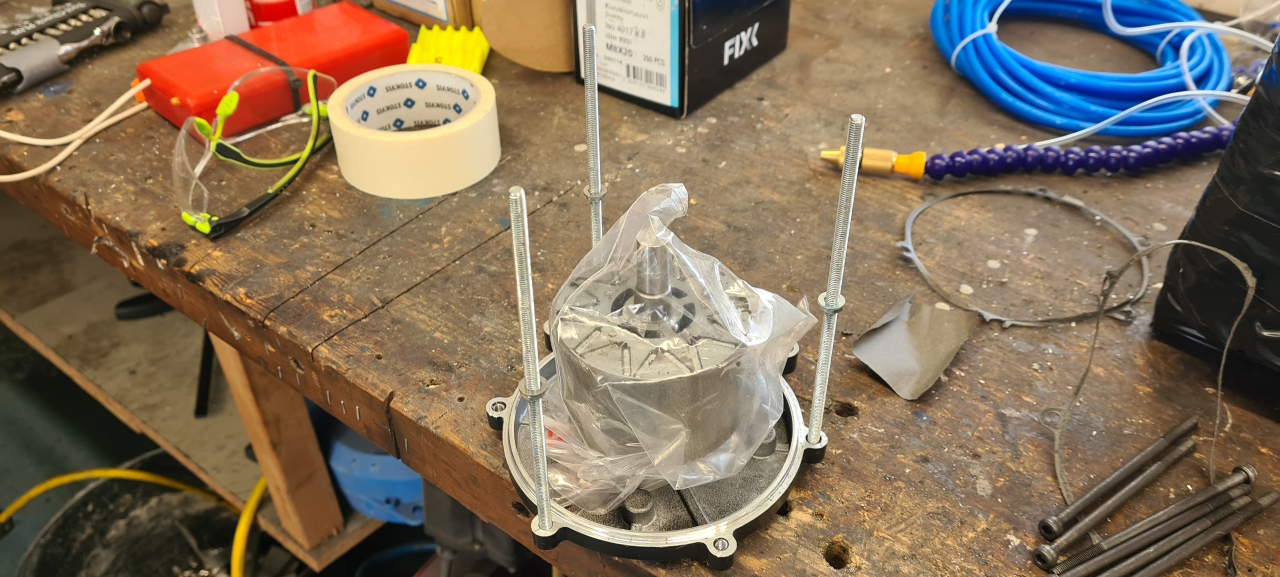

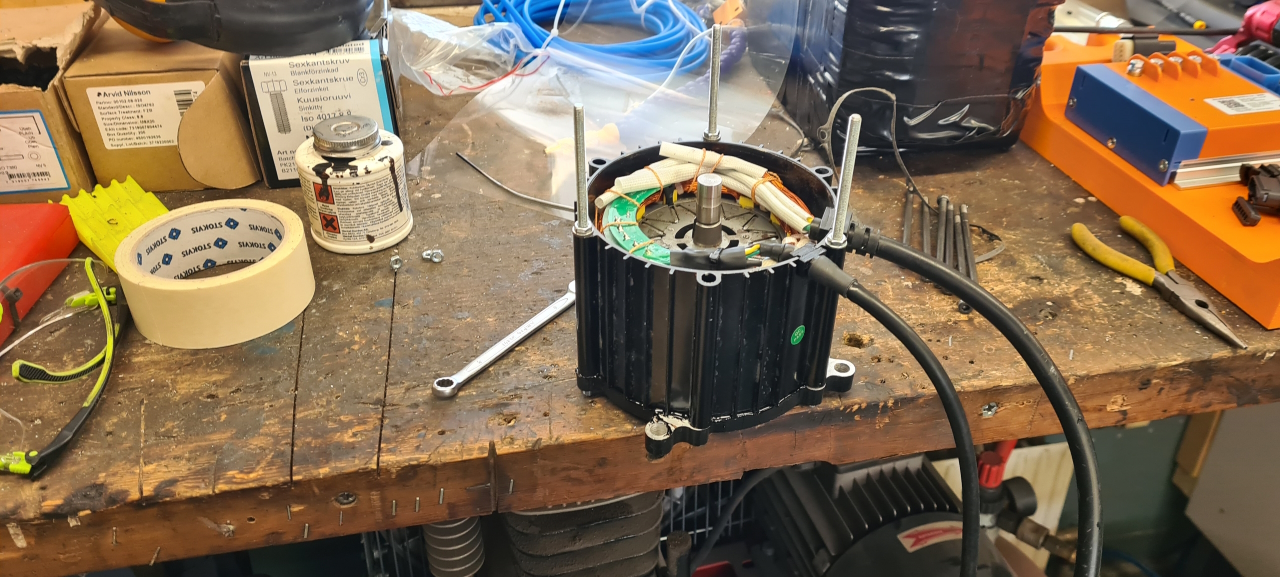

So, since the magnets in the rotor was super strong I’ve been a bit nervous about re-assembling the motor, but I got an idea..

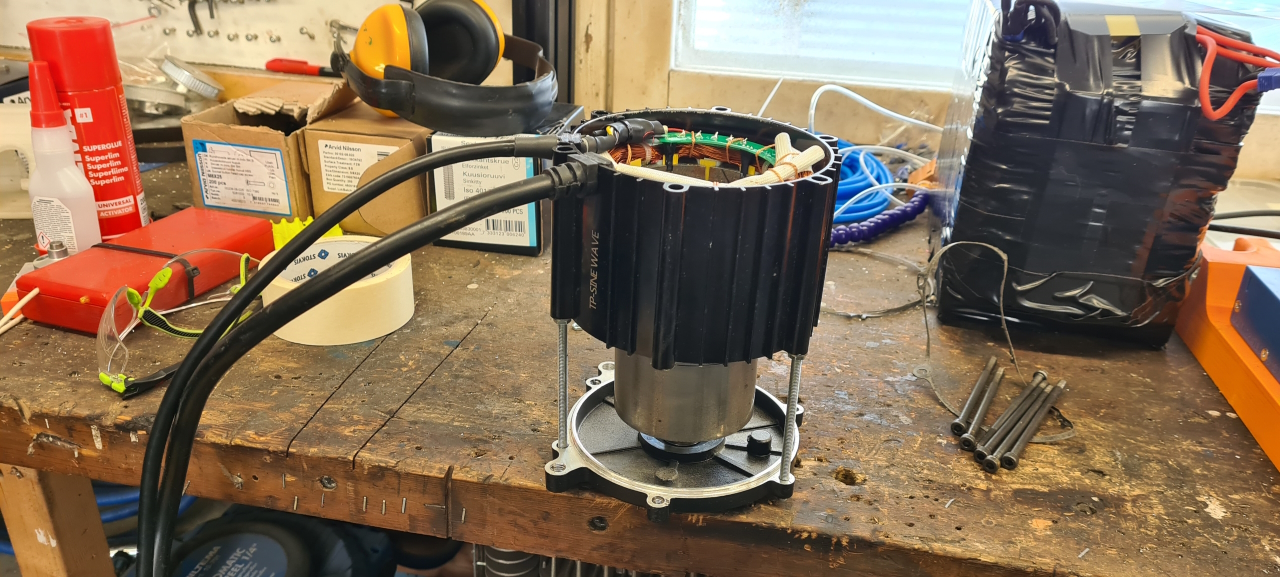

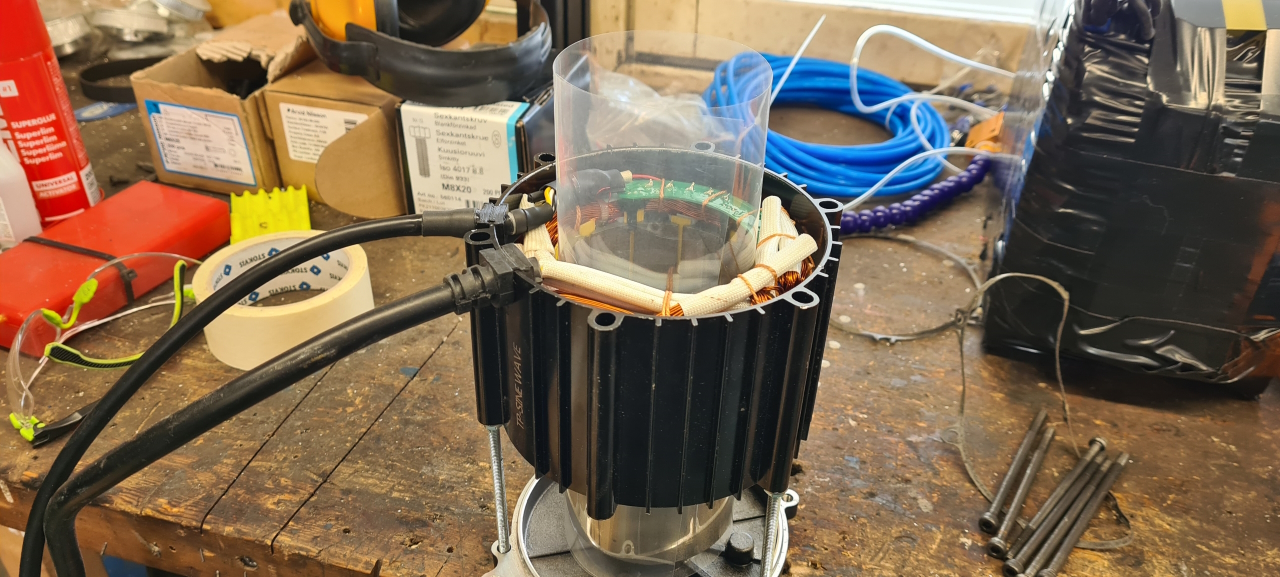

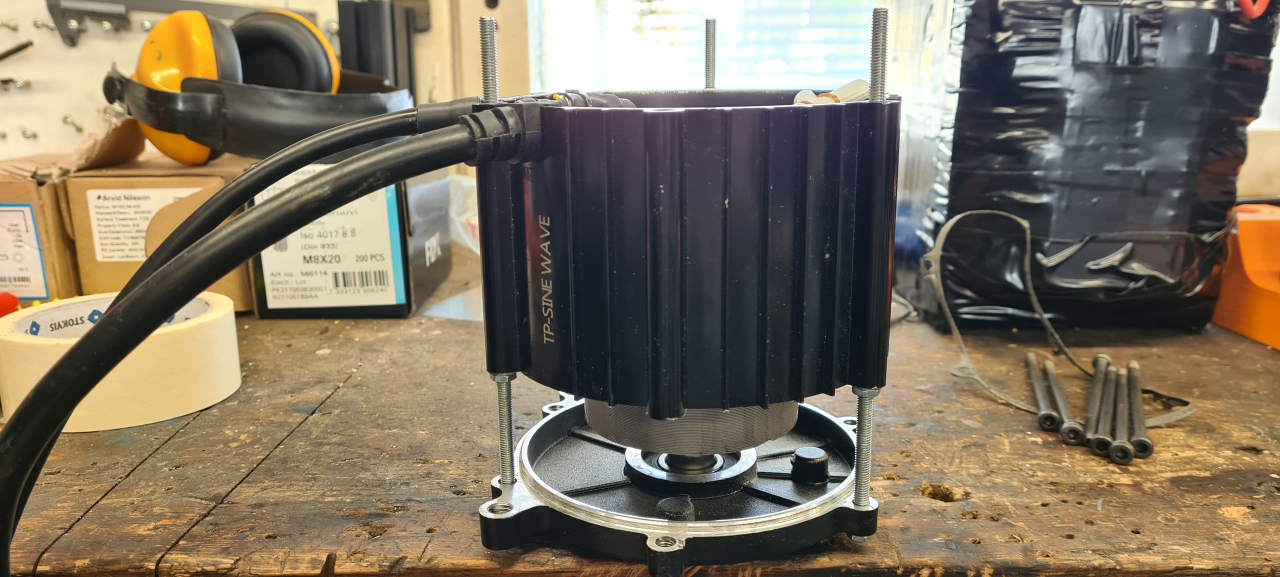

So, now it was just a matter of easing the stator down all the way. Most of the way I could just turn the nuts by hand but it’s the last centimeters that are hardest to control but the three-nut-solution made it super easy.

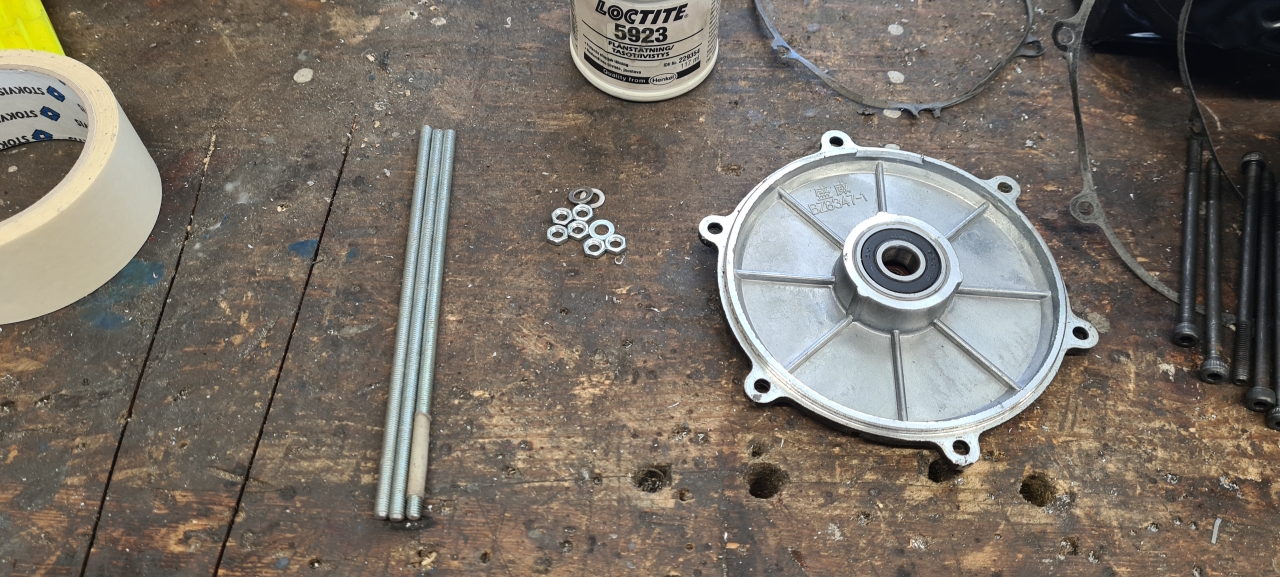

Frame preparation

To be continued..